SpaceSaver 8×4 with Sliding Door

$2,860.00 – $3,435.00

- Origin: Made In Canada

- Material: Western Red Cedar

- Sustainability: PEFC & WRCA Certified

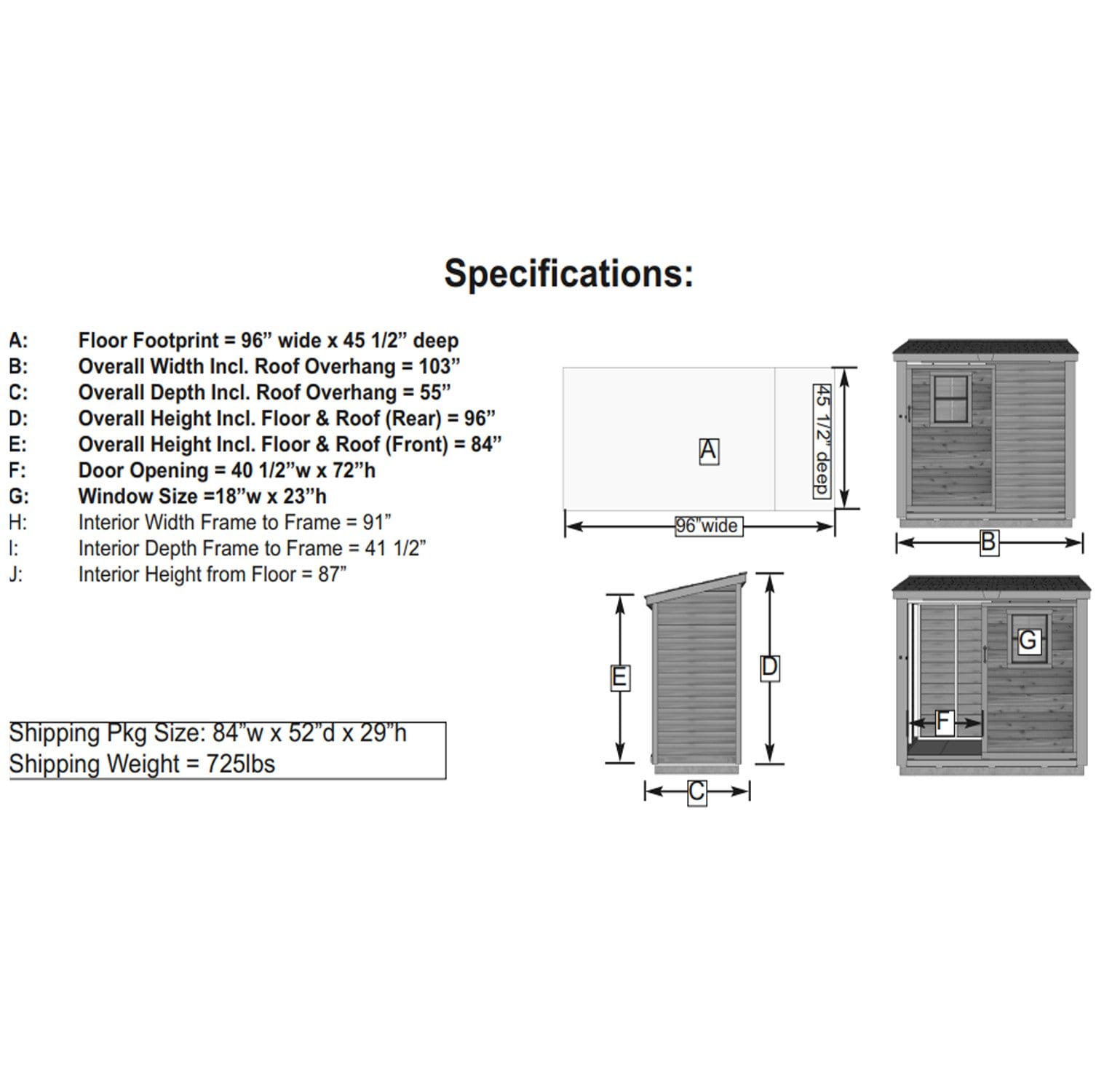

- Footprint: 96 in W x 45.5 in D x 96 in H

- Storage Capacity: 190 cubic feet

- Warranty: 3 Limited Warranty*

Free Shipping

Satisfaction Guarantee

Financing Available

Painter’s Choice® Finger-Jointed Clear Siding caters to artists seeking a pristine canvas. Its clear surface, devoid of knots, provides an ideal backdrop for painting, ensuring that every stroke is showcased with clarity. Whether drawn to the rugged charm of knots or desiring a flawless painting surface, the choice between Classic Knotty and Painter’s Choice® hinges on personal aesthetic preferences.

*Painter's Choice® Clear Siding comes naturally unfinished and is ready to be painted.

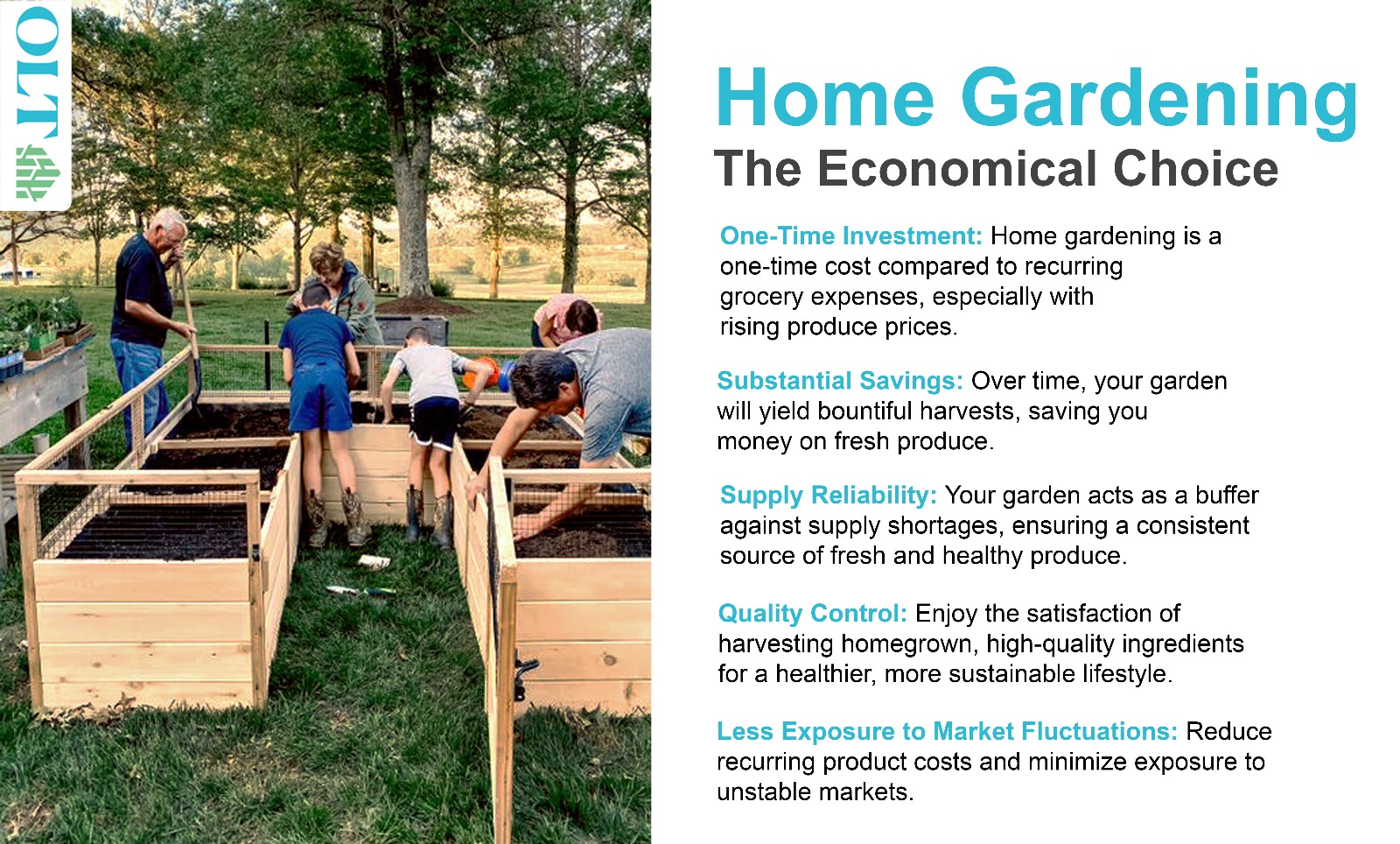

1. Produce Savings: You'll have access to fresh, organic produce without the markup associated with store-bought items.

2. Less Frequent Trips to the Store: Having a variety of fresh produce at home means fewer trips to the grocery store. This can help you avoid impulse purchases and save on transportation costs.

3. Lower Overall Food Costs: While there are initial investments in seeds, soil, and tools, these costs are often offset by the savings on groceries over time.

4. Cuts on Specialty Ingredients: Growing herbs at home can save money, especially if you regularly buy fresh herbs from the store.

5. Preserving & Canning: If you have a surplus of fruits and vegetables, you can preserve them through canning, freezing, or drying.

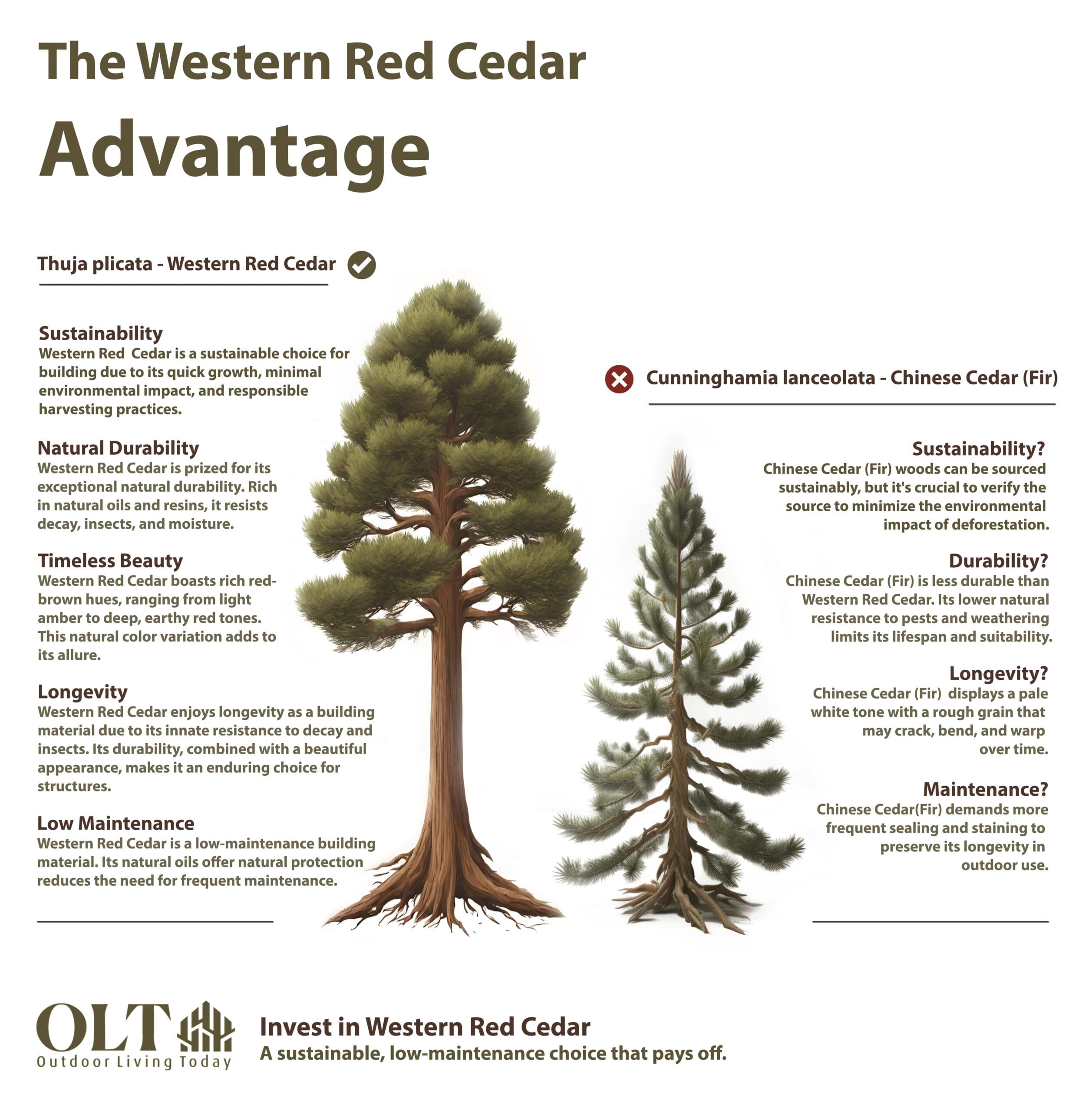

Western Red Cedar is a naturally stunning building material with deep, tonal properties that accentuate the richly textured wood grains and exposed heartwood.

For centuries, the Western Red Cedar has been celebrated by the Pacific Northwest Coast First Nations as the “Tree of Life” using it to build longhouses, canoes, and totem poles.

Red cedar’s reputation for being a naturally durable wood makes it perfect for all outdoor projects. The wood is lightweight and valued for its high natural resistance and decay properties.

It is less susceptible to moisture, insect damage, and fungi growth. Cedar is also water damage resistant and can successfully weather long periods of heavy rain and other weather extremes such as snow, hail, and strong winds.

With its unsurpassed natural beauty, centuries of proven performance, low environmental impact, and natural resistance to decay/insects it’s clear to see the advantage of quality Western Red Cedar.

To learn more about Western Red Cedar vs. Imitation Products Click Here.

For those looking for help with installation, we have partnered with YesKandu On-Demand Home Services for an extra cost

Yes.

We ship to serviceable areas in the continental US & Canada, not Puerto Rico, or the Virgin Islands. In any other areas including Hawaii and Alaska, we can ship to a freight forwarder located on the mainland of the US.

Our freight partners generally describe a serviceable area as anywhere accessible by a large freight truck or where roads are regularly maintained and items can be delivered safely. This broad definition applies to most urban and non-urban places.

Areas not considered serviceable are exceptionally rural areas that are not safely accessible by a large truck. If you have concerns that this may be applicable to you, then you can also have your items shipped to the freight terminal and pick them up yourself.

Please feel free to give us a call at 1 888-658-1658, and we will be glad to assist you with any other questions you may have about this.

Our products ship quickly in 1-3 weeks!

Our office will contact most customers with larger sized orders once the order has been processed. We will discuss the delivery process and transit time before your order is shipped. Once on route our shipping team will send tracking information. This conversation will also to allow you to make changes to your order, and or ask any further questions that you may have.

Delivery estimates depend on a variety of factors, from distance to weather. You will be able to contact the carrier yourself with the tracking number, and our team is ready if you need assistance.

We are a Canadian Company, and we manufacture in Penticton, British Columbia, Canada.

Standard: Outdoor Living Today 1-Year Warranty

All structures purchased from Outdoor Living Today are covered for a period of one year for defects in manufacturing and workmanship. In the event of a missing or broken piece, simply call the Outdoor Living Today Customer Support Line @ 1-888-658-1658 within 30 days of the delivery of your purchase.

Outdoor Living Today Limited 3-Year Warranty (Effective on Purchases April 2024 – Onward)

Our Limited 3-year warranty is a testament to our commitment to quality and durability.

This limited warranty protects against rot and decay only on the Cedar substrate contained in our Shed, Playhouse, Gazebo, and Pergola products. *Raised Garden Beds qualify only if the interior of the beds is fully lined with a waterproof membrane before filling the garden with soil.

We understand the importance of preserving the structural integrity and aesthetic appeal of your property. With this limited warranty, you can enjoy peace of mind, knowing that the Cedar is protected from exposure to the elements.

Embrace a worry-free experience as we stand behind our products, ensuring they withstand the test of time.

CONDITIONS & LIMITATIONS

We require that the following conditions are met to ensure your warranty remains valid...

Your OLT Product Must Be Assembled Within 90 Days Of Delivery. This is to prevent any warping, shrinkage, or damage that may result from materials sitting for too long. To validate your warranty, we ask you to verify that your OLM Product structure is completed within this timeline by providing photo documentation of your finished build. You may submit your photos using the link below

Proper Base: Your unit must be placed on a correct and stable base to avoid unnecessary wear and damage. The responsibility for setting up a suitable base lies with the purchaser.

Proper Maintenance: Regular maintenance is essential. This includes re-painting or re-staining and keeping the perimeter and underside of the building free from vegetation and debris. Regular re-attaching of loose hardware, nails that have popped out, and re-tightening screws which have come loose.

No Relocation or Alteration: Moving the building from its original location or significantly altering the structure may void the warranty.

Exclusions: Damage due to acts of nature, including tornadoes, hail storms, fires, and more, are not covered by this warranty.

Original Purchaser: This warranty applies exclusively to the original purchaser of the product.

Timely Reporting: Any failure or defect must be reported to Outdoor Living Today within 7 days after discovery using our easy claims system on our website. https://www.outdoorlivingtoday.com/olt-customer-claims/

No Liability for Personal Property: Outdoor Living Today is not liable for any loss or damage to personal property or contents placed in the building, including damage caused by any defect in the building. Any products installed such as floor coverings or wall and ceiling coverings are not included.

No Indirect or Consequential Damages: We will not be responsible for any indirect, incidental, or consequential damages, nor for failures caused by events, acts, or omissions beyond our control, such as misuse or improper maintenance.

(See our helpful Site Prep page, as well as your included assembly manual for the correct foundation for your product.) https://www.outdoorlivingtoday.com/site-prep-before-your-product-arrives/

Please contact our customer support for any additional guidance on best practices for maintaining your items for optimal performance and longevity.

1 888-658-1658

Ramp Option:

Ramp Option: